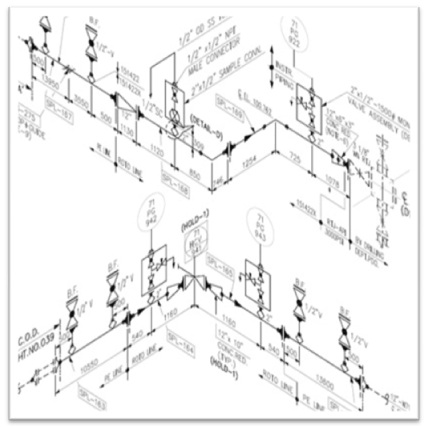

Usually, FFW will occur at the nozzle of equipment or tie-in locations.Īssembled Drawing Piping isometric drawing symbolsįor reading and understanding a piping isometric drawing, one should learn the piping isometric drawing symbols thoroughly. This FFW is defined by the designer if he/she could foresee that the spool might require some adjustment before the final fit-up, so at the location of FFW that has been marked, it will be given some pipe length tolerance (commonly 150-300mm). There is one more type of weld that is known as field-fit weld (FFW). One sheet of Isometric drawing normally has few spools.Įvery weld that is assembled between spools at the construction site is termed a field weld (FW).

These small pipe pieces are termed piping spools. The complete piping system is separated into pieces that are transported to the site for erection.

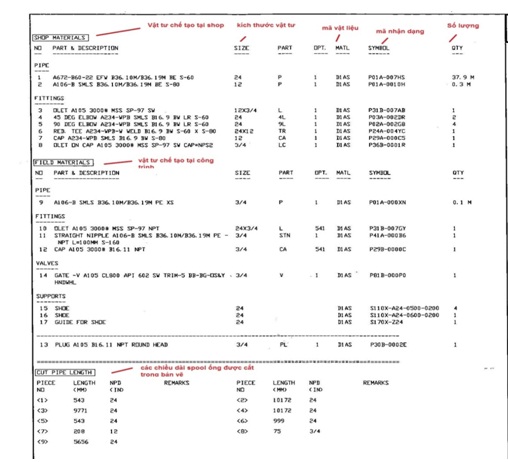

Isometric drawings also inform which piping should be constructed at the fabrication shop and which should be assembled at the construction/platform field itself. For example, if double piping is modeled by mistake, it will read the double quantity of material.ĥ. However, It is always better to check and verify as there could be some issues with the modeling itself that may cause discrepancies in material and quantity. Imagine complex design and yet orthographic drawings are used for construction, that is really a headache. The following figure gives an example of how one Isometric drawing can represent three orthographic drawings. Piping Isometric drawings are popular because of their simplicity yet efficiency to convey complex information.

0 kommentar(er)

0 kommentar(er)